Five Critical Design Considerations for Conveyor Systems in Automated Manufacturing

Posted on by Joseph DaSilva, Design Engineer

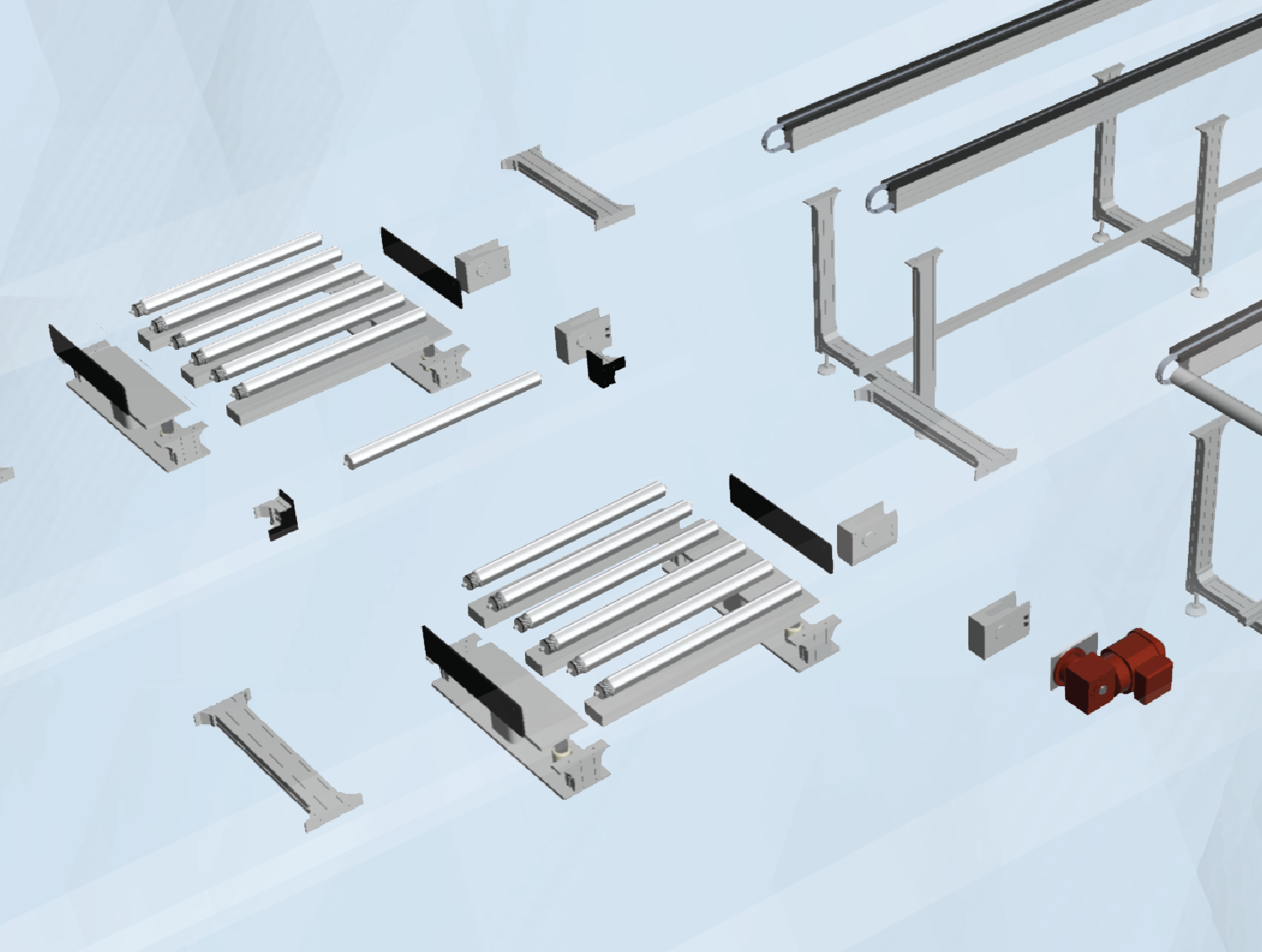

In today’s fast-paced manufacturing environments, conveyor systems serve as the backbone of material handling, optimizing efficiency, reducing labor costs, and ensuring smooth workflows. However, designing the right conveyor system isn’t as simple as just moving parts from one station to another. Engineers must carefully evaluate several critical factors to ensure their conveyors perform reliably and integrate seamlessly.

Whether you’re designing a new production line or upgrading an existing system, take a ride through this guide learn the five most important design considerations for creating an efficient and durable conveyor system.

1. Load Capacity and Throughput: Designing for Performance

Understanding the weight, size, and material of the product being transported is crucial to prevent failures and inefficiencies. Incorrectly specifying these factors can lead to premature wear, increased downtime, and costly repairs.

Key Factors to Consider:

- Weight Capacity: Determine the maximum load your conveyor will handle. This impacts motor selection, belt strength, and structural integrity.

- Throughput Requirements: Consider peak production demands and future growth. Underestimating throughput can lead to bottlenecks and inefficiencies.

- Material Properties: Is the material abrasive? Irregularly shaped? Fragile? These characteristics influence belt choice, roller type, and conveyor speed.

2. Selecting the Right Conveyor Drive System

The conveyor drive system is the heart of your material handling solution. We offer various drive configurations to meet your space constraints and maintenance requirements.

Common Drive Types:

- Direct Drive: Reduces maintenance by eliminating components like chains and belts, increasing system longevity.

- Chain Drive: Cost effective and durable, the motor can be placed above or below the conveyor and tucked out of the way of operators.

- Belt Drive: Quiet and strong, ideal for high-speed or high-load applications.

Engineering Tip:

Consider using variable frequency drives (VFDs) to fine-tune conveyor speed, optimizing performance based on load variations and energy efficiency goals.

3. Automation Integration: Conveyors in Smart Manufacturing

Modern manufacturing relies heavily on automation, and conveyors must integrate seamlessly with robotics, sensors, and control systems.

Essential Integration Features:

- Precision Indexing: Ensures products are accurately positioned for robotic pick-and-place operations.

- Communication Protocols: Use industry-standard protocols like Ethernet/IP, PROFINET, and Modbus for connectivity.

- Smart Sensors: Implement IoT-enabled sensors for real-time monitoring, predictive maintenance, and efficiency tracking.

Engineering Tip:

When integrating with automation, consider how quickly and accurately you need to get your product in position. This can greatly influence which platform and process we recommend to achieve your goal! mk North America’s precision conveyor solutions offer high repeatability for robotic applications.

4. Material Selection for Durability and Compliance

Conveyor materials impact longevity, maintenance, and regulatory compliance. Engineers must select materials that align with their industry’s operational and safety requirements.

Material Choices:

- Stainless Steel: Ideal for food, pharmaceutical, and cleanroom environments due to its corrosion resistance and hygiene properties.

- Modular Plastic Belts: Provide easy maintenance, customization options, and resistance to wear and chemical exposure.

- Coated Rollers and Frames: Extend lifespan and minimize wear in high-friction applications.

Engineering Tip:

If your system operates in extreme temperatures or requires frequent washdowns, consider FDA-approved or heat-resistant materials to ensure compliance and longevity.

5. Optimizing Space and Conveyor Layout

Proper conveyor layout planning maximizes floor space, improves workflow efficiency, and ensures ease of maintenance. A poorly planned layout can lead to congestion, inefficient routing, and safety hazards.

Layout Considerations:

- Space Utilization: Vertical conveyors or overhead systems can free up valuable floor space.

- Ergonomics & Safety: Ensure conveyor heights and workstations align with operator comfort and safety standards.

- Maintenance Accessibility: Design layouts that provide easy access to belts, motors, and control panels for routine servicing.

Engineering Tip:

Custom design your per-spec conveyor using a CAD tool. Explore mk North America’s CAD360! to design and customize your ideal per-spec conveyor system in minutes.

Conclusion

A well-designed conveyor system enhances manufacturing efficiency, reduces operational costs, and extends equipment lifespan. By carefully considering load capacity, drive systems, automation compatibility, material selection, and space optimization, engineers can develop solutions that support long-term operational success.

Want to Learn More?

Contact mk North America today for expert guidance on selecting and designing the best conveyor solutions for your manufacturing needs. To find your local regional sales manager, click here or for general inquiries, you can fill out our contact form and we will respond to you within 24 hours.