The Role of Aluminum Framing in Industrial Automation

Posted on by Christer Osterling

In the ever-evolving world of industrial automation, adaptability and efficiency are crucial for manufacturers looking to remain competitive. Engineers and designers require flexible, durable, and cost-effective solutions that can accommodate evolving production demands. T-slot aluminum framing systems have emerged as a critical component in this landscape, offering modularity, ease of assembly, and customization options that traditional materials such as steel simply cannot match.

This article explores the role of aluminum framing in industrial automation, highlighting its benefits, common applications, and how it supports innovative automation solutions.

What is T-Slot Aluminum Framing?

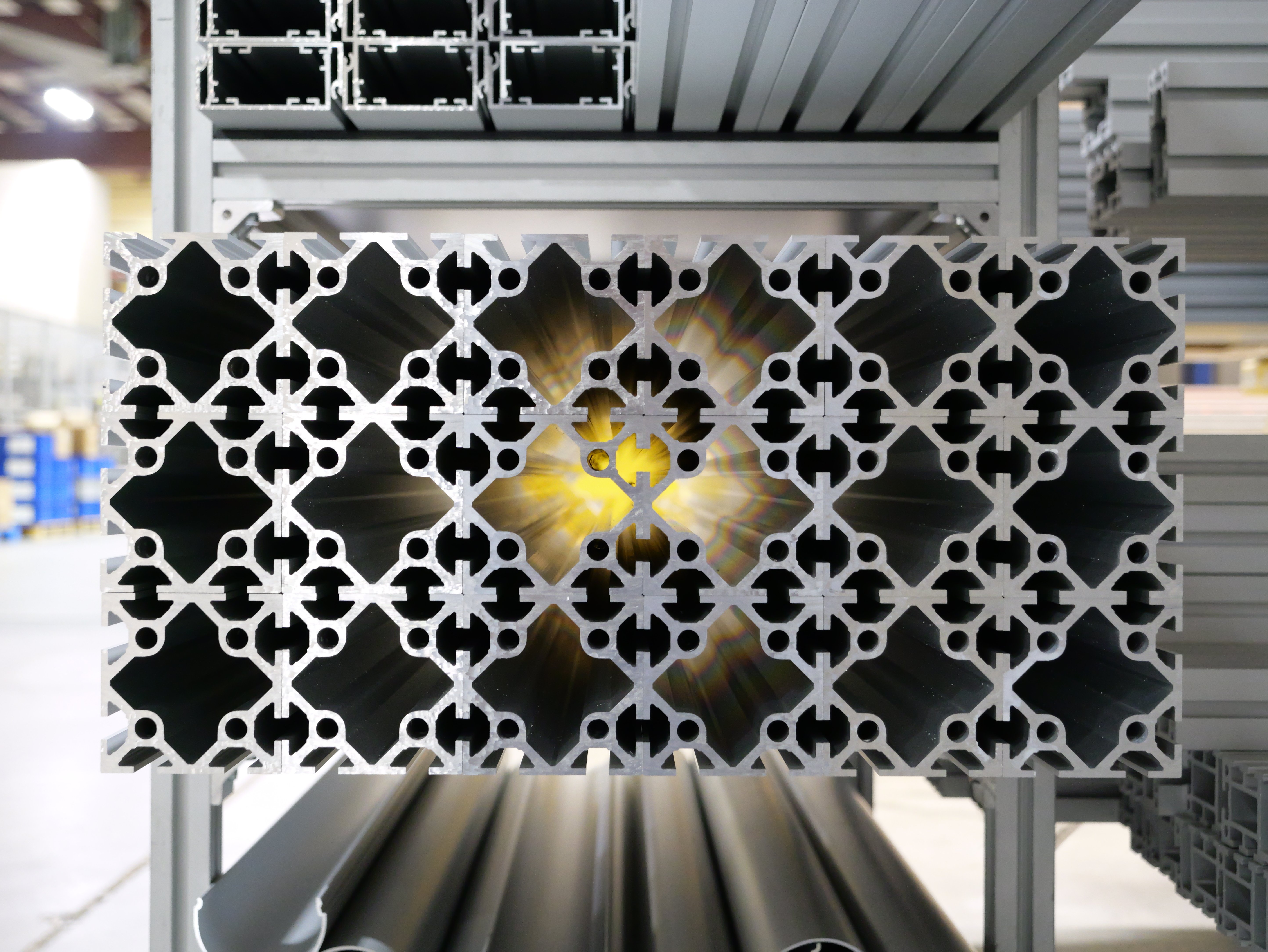

T-slot aluminum framing consists of extruded aluminum profiles with a unique “T” shaped groove along each side. This groove allows for simple yet secure connections with various fasteners and accessories, enabling engineers to build and modify structures without welding or specialized machining.

The modular nature of T-slot aluminum makes it an ideal choice for engineers who need to design workstations, machine enclosures, safety guards, and conveyor systems, among other industrial solutions. Because of its versatility, aluminum framing is widely used in industries such as automotive, aerospace, robotics, packaging, and material handling.

Advantages of T-Slot Aluminum Framing in Industrial Automation

1. Modularity and Flexibility

One of the standout advantages of T-slot aluminum framing is its modularity. Unlike traditional steel structures, which require welding and complex fabrication, aluminum frames can be assembled and reconfigured with minimal effort. This flexibility allows engineers to quickly adapt systems to new processes, improving workflow efficiency and reducing downtime.

For instance, a production line may need modifications to accommodate new equipment or changes in manufacturing requirements. With aluminum framing, adjustments can be made by simply loosening and repositioning fasteners rather than cutting and rewelding steel frames.

2. Ease of Assembly and Integration

T-slot aluminum framing is designed for straightforward assembly. Using basic hand tools, engineers can quickly construct frames without the need for welding, grinding, or painting. This simplifies the setup process, reducing both labor costs and project lead times.

Additionally, aluminum framing integrates seamlessly with automation components such as sensors, actuators, and conveyors. Engineers can mount brackets, safety enclosures, and electrical wiring directly onto the frame using standard connectors, minimizing additional hardware and ensuring a clean, professional installation.

3. Lightweight Yet Strong

Aluminum is significantly lighter than steel while still offering impressive strength and durability. This weight advantage is particularly beneficial in automation applications where mobility is required, such as robotic work cells and material handling systems.

The reduced weight also contributes to lower transportation costs and easier handling during assembly and installation. Despite its lighter profile, aluminum framing provides excellent load-bearing capabilities and structural integrity, making it suitable for heavy-duty industrial applications.

4. Corrosion Resistance and Longevity

Unlike steel, which is prone to rust and requires coatings or treatments to maintain its integrity, aluminum naturally resists corrosion. This makes T-slot aluminum framing ideal for environments exposed to moisture, chemicals, or extreme temperatures.

For industries such as food processing and pharmaceuticals, where hygiene and cleanliness are paramount, anodized aluminum framing provides an additional layer of protection against contamination. This ensures long-term reliability and reduces maintenance requirements over time.

5. Customization and Scalability

Every automation application is unique, requiring tailored solutions to meet specific operational needs. T-slot aluminum framing offers virtually unlimited customization options, with a wide range of profiles, fasteners, and accessories available to engineers.

Whether designing a compact workstation or a large-scale automated assembly line, engineers can select from different profile sizes, surface finishes, and structural reinforcements to optimize performance. Furthermore, the scalability of aluminum framing allows businesses to expand or modify their systems as production needs evolve.

Common Applications of Aluminum Framing in Industrial Automation

1. Machine Guarding and Safety Enclosures

Ensuring worker safety is a top priority in industrial settings. T-slot aluminum framing is widely used to construct machine guarding, safety enclosures, and protective barriers that prevent accidental contact with moving parts or hazardous equipment.

These enclosures can be designed with transparent polycarbonate panels for visibility, sliding doors for easy access, and interlocks for enhanced safety compliance. The lightweight nature of aluminum also allows for quick modifications or reconfiguration as safety requirements change.

2. Workstations and Ergonomic Assembly Stations

Manufacturing and assembly processes often require workstations that are both ergonomic and adaptable to different tasks. T-slot aluminum framing enables engineers to design adjustable-height workbenches, tool racks, and conveyor-supported workstations tailored to operator needs.

By incorporating accessories such as lighting, monitor mounts, and storage bins, these workstations enhance productivity and comfort while reducing strain on workers. The modularity of aluminum framing ensures that workstations can be easily adjusted or expanded as production demands increase.

3. Conveyor Systems and Material Handling Solutions

Efficient material handling is crucial for optimizing workflow and reducing bottlenecks in production lines. Aluminum framing is commonly used to construct conveyor support structures, roller stands, and transfer stations that facilitate smooth product movement.

T-slot aluminum allows for easy integration of conveyor belts, guiding rails, and automation components such as sensors and actuators. This adaptability ensures that conveyor systems can be fine-tuned for maximum efficiency and reliability.

4. Robotic Work Cells and Automation Frameworks

As automation and robotics continue to transform manufacturing, engineers require robust and adaptable structures to support robotic arms, pick-and-place systems, and automated assembly lines. T-slot aluminum framing provides a lightweight yet sturdy framework for robotic applications.

With precise mounting options and modular components, engineers can design robotic work cells that accommodate different payloads and movement ranges. The ability to easily adjust or expand these frameworks ensures that automation systems remain agile and responsive to changing production needs.

Selecting the Right Aluminum Framing System

When choosing an aluminum framing system for industrial automation, several factors should be considered:

- Profile Size and Load Capacity: Selecting the right profile size ensures that the structure can support the required loads without compromising stability.

- Surface Treatment and Coatings: Anodized aluminum offers additional corrosion resistance and durability.

- Compatibility with Accessories: Ensure that the framing system supports necessary accessories such as fasteners, panels, and mounting brackets.

- Supplier Support and Customization Options: Working with a trusted supplier like mk North America ensures access to high-quality components, engineering expertise, and tailored solutions for specific automation needs.

Conclusion

T-slot aluminum framing has revolutionized industrial automation by providing engineers with a modular, lightweight, and highly adaptable structural solution. Its ease of assembly, durability, and scalability make it an invaluable asset for designing workstations, conveyor systems, safety enclosures, and robotic frameworks.

As automation technologies continue to advance, the demand for flexible and cost-effective solutions will only grow. By leveraging the benefits of aluminum framing, manufacturers can enhance efficiency, streamline production, and maintain a competitive edge in the evolving industrial landscape.

For more information on how aluminum framing can support your automation needs, visit mk North America and explore our range of high-quality T-slot aluminum solutions.