Problem:

A manufacturing company in Ohio, specializing in precision metal stamping for the automotive and other high-performance industries, faced challenges in efficiently removing scrap from their stamping operations. They required a conveyor solution that fit within tight spatial constraints, operated with minimal maintenance, and stayed within a strict budget. The conveyor needed to handle scrap material with a payload of approximately 10 lbs. while integrating seamlessly with their existing equipment. Additionally, the solution required a non-magnetic design to prevent metallic stamping scraps from sticking to the conveyor surface.

Solution:

mk North America designed a custom GUF-P 2000 flat belt conveyor to meet the customer’s specific requirements. Key features of the solution included:

- Durable Belt Design: The conveyor was equipped with a flat belt made from a robust material designed to withstand daily wear and tear.

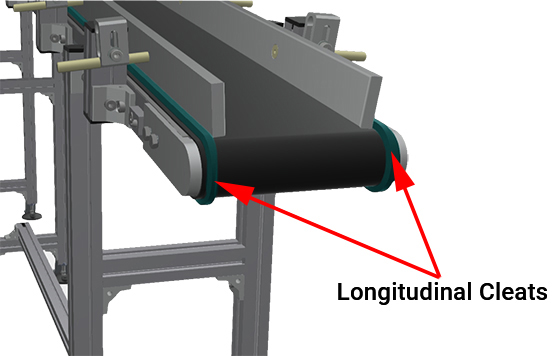

- Longitudinal Guides: The belt featured continuous longitudinal guides on the belt surface – which ensured scrap materials remained within the middle of the belt and not within the conveyor or on the floor.

- Custom Side Rails: Inset side rails were added to contain scrap while remaining compatible with the belt’s top side guides.

- Non-Magnetic Slider Bed: A non-magnetic slider bed was used to ensure that metallic stamping scraps would not stick to the conveyor, maintaining smooth operation and reducing cleaning requirements.

- Roller Brush Mechanism: A roller brush installed on the underside of the conveyor’s top surface actively removed any metal scraps clinging to the belt, ensuring a clean and efficient process.

- Height and Layout: The conveyor was designed with an infeed height of 3 feet and a discharge height of 4 feet to fit seamlessly within the customer’s stamping operation workflow.

- Specialized Stands: Conveyor stands were designed with a specific inset to accommodate the customer’s existing equipment layout, ensuring smooth integration.

mk collaborated closely with the customer, iterating on the design to deliver a solution that balanced their budget with the technical demands of their stamping centers.

Results:

The custom GUF-P 2000 flat belt conveyor provided the Ohio-based manufacturer with an efficient and reliable scrap removal solution, offering:

-

Enhanced Durability and Longevity: The durable belt design, combined with the non-magnetic slider bed and roller brush mechanism, minimized wear and tear while ensuring the effective removal of metallic scrap.

|

|

mk North America’s innovative engineering and dedication to customer collaboration resulted in a tailored solution that enhanced stamping operations while streamlining scrap removal processes.

mk Products Featured